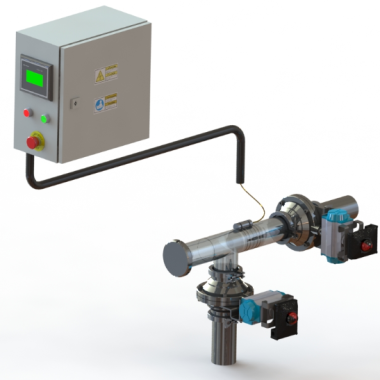

SLR system is an economical way to maximize efficiency in product recovery. It can be used for product removal, reduce contamination in product exchange or for cleaning separation. It consists of a launcher and a receiver station that are installed at the ends of the pipeline, being a device that facilitates the introduction and subsequent removal of the Pig. Pigs can be supplied with magnets installed inside, to make their location easier. Recovery of residual product: The SLR System used after product transfer, recovers residual, cleans pipeline walls and reduces the amount of effluent in washing.

Product Separation: The SLR System used to exchange products prevents contamination and reduces transfer time.

Product Reduction: The SLR System allows solvents or cleaning fluids to be confined between two Pigs, significantly reducing the volume of generated effluent.

Recommendations to improve the performance of the SLR System, we recommend that pipes have the following characteristics:

Long-ray curves: 3D or 5D, if possible;

Full passage valves, i.e., with internal diameter compatible with the internal diameter of the pipeline;

Internally smooth transitions;

Welds and joints must not have bulges to the inner side of the pipeline;

The flow and pressure of the liquid or gas used to displace the Pig must be controlled in the range of 1 to 2 m/s. Speeds beyond this range cause pig seal deficiency, pipe vibration, and pig life reduction.

Ovalizations are less than 2%.

SIZE

1 1/2″ to 42″

OPTIONAL

Pig Pass Indicator.

APPLICATIONS

Food, hygiene and pharmaceutical industries.